- Company

-

-

-

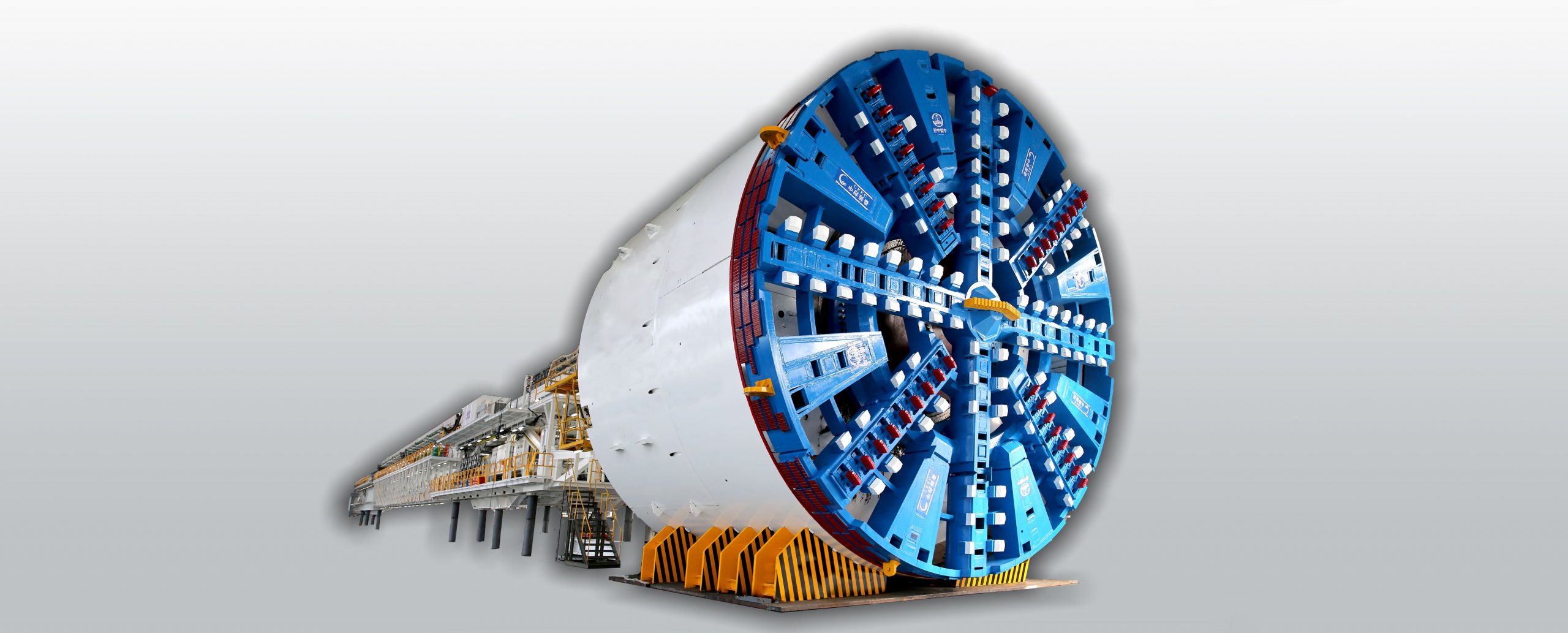

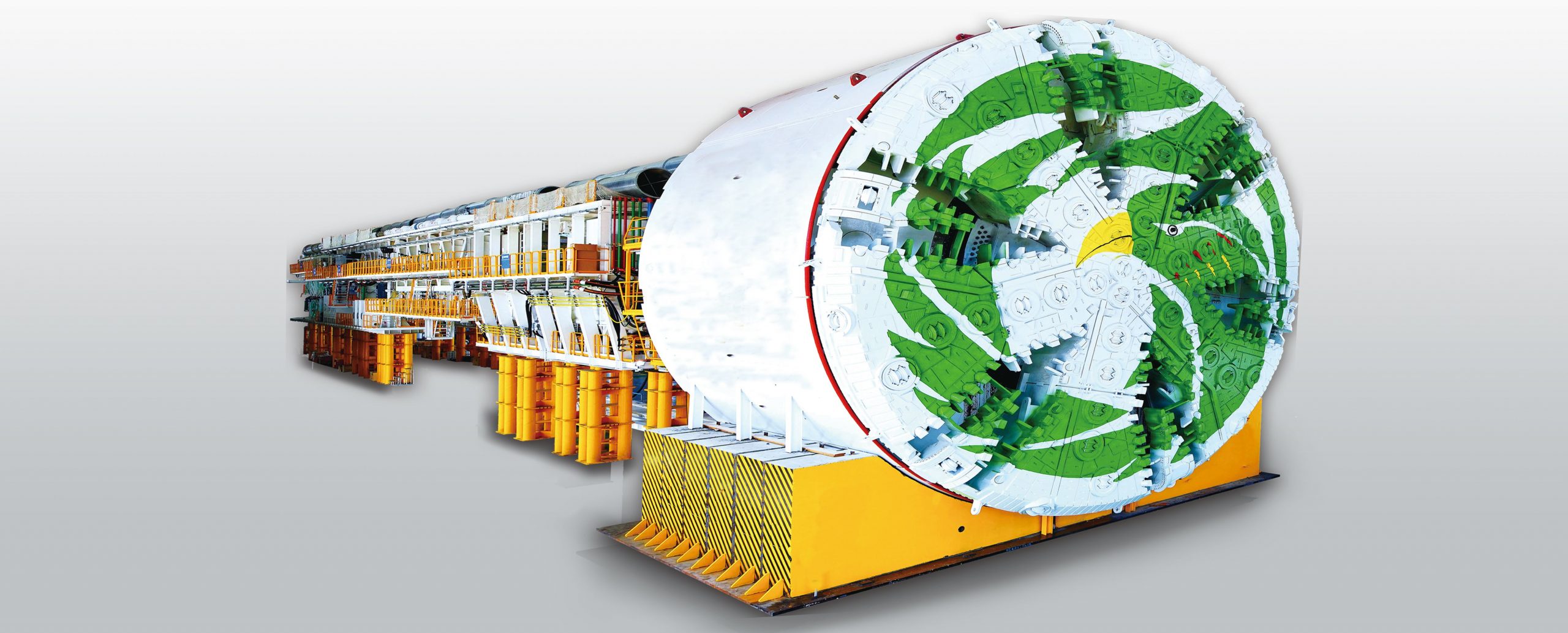

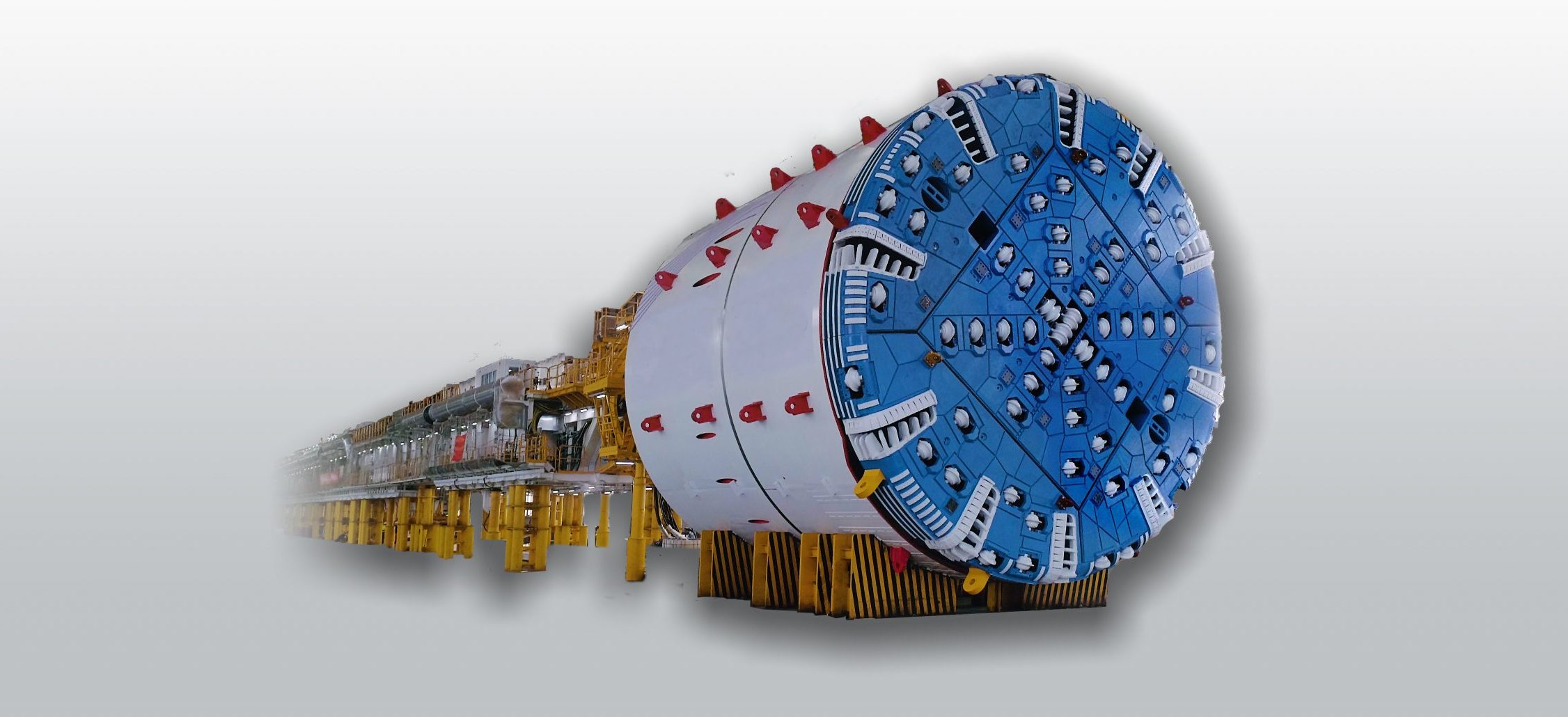

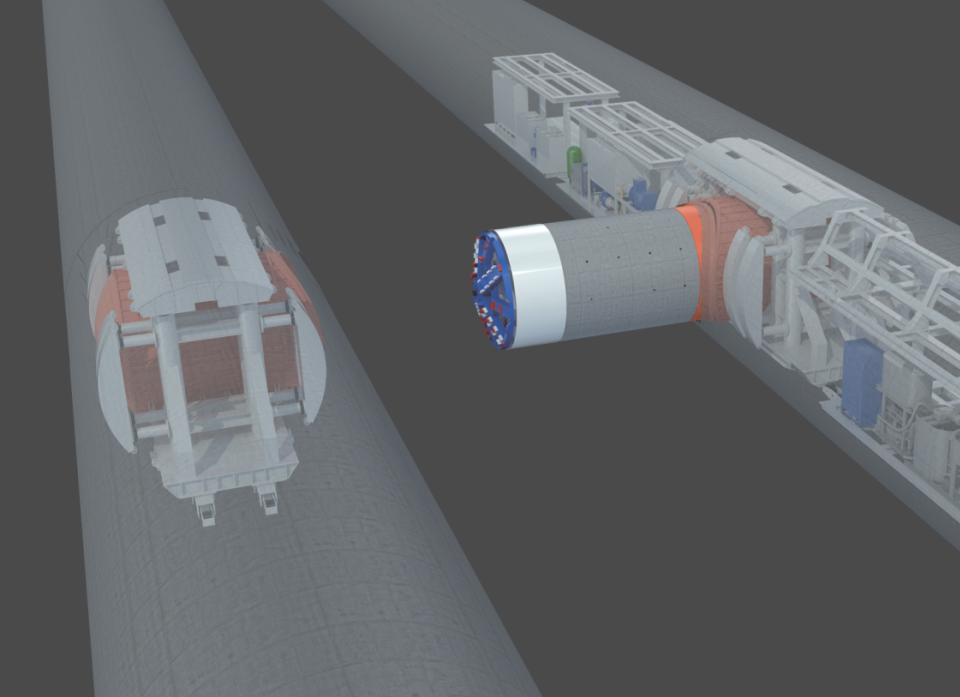

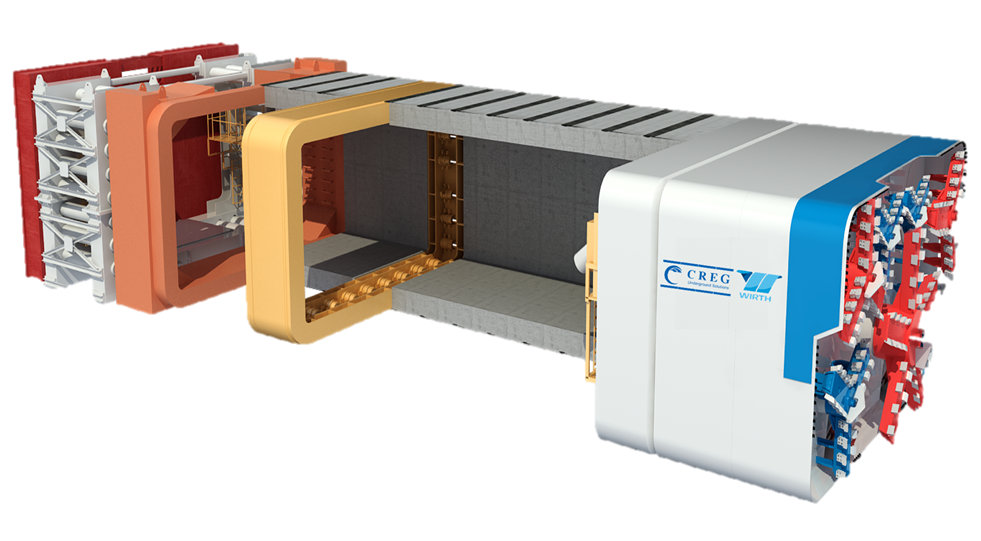

CREG is a worldwide underground

solutions provider for a wide range of mechanized tunnelling technology and services.

-

-

-

-

-

- Products

-

-

-

CREG is committed to creating a world TBM brand with innovation-driven development, and actively embraces new technologies, taking it as its own duty to be the first-class underground tunnelling service provider.

- Explore All Products

-

-

-

-

- Services

- References

- News

- Contact Us